Lubrication systems

Perma-tec’s single and multi-point lubrication equipment is suitable for almost all industrial needs and applications.

Long experience, numerous patents and certificates make Perma-tec a leading manufacturer of lubrication systems

Perma-tec has been manufacturing lubrication equipment solutions for 50 years. All Perma products are developed, tested and manufactured in Germany. Every 11 seconds somewhere in the world, a Perma lubricator is either installed or replaced. Since 1964, Perma-tec has sold as many as 60 million lubricants worldwide for the mining, steel, power plant, mechanical engineering, automotive, food, plastics and chemical industries.

Lubricator with the help of Kraftmek experts

With the help of our experts, a lubricator that meets your needs can be found easily and quickly. We will be happy to answer any questions you may have about the equipment, installation or use. Worth asking!

Single point lubrication systems

The single-point lubrication system can be installed directly at the desired lubrication point or alternatively further away, so that vibration or movement does not interfere with lubrication. An electrochemical or electromotive controlled system can be used in the lubricator. The lubricant discharge time is freely selectable between 1 and 12 months. Installation and use is really easy and fast.

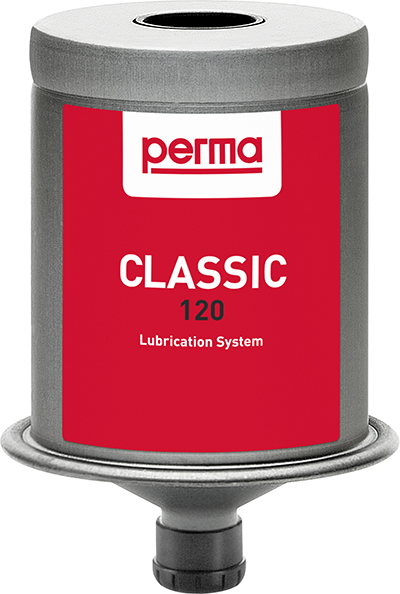

Classic

Perma Classic is a metal-framed automatic grease that can be activated with a 120 cm³ activator screw. The discharge time is 1, 3, 6 or 12 months depending on the selected activator screw.

Perma Classic works best in an environment where the temperature is 0 … + 40 ° C. Perma Classic produces a maximum pressure of 4 bar using an electrochemical reaction and withstands well even in harsh conditions. Perma Classic has an EX rating.

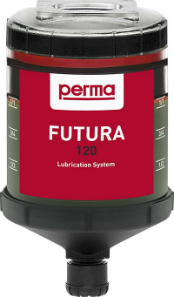

Futura

Perma Futura is a plastic-framed automatic grease that can be activated with a 120 cm³ activator screw. The discharge time is 1, 3, 6 or 12 months depending on the selected activator screw.

Perma Futura works best in an environment where the temperature is 0 … + 40 ° C. Perma Futura produces a maximum pressure of 4 bar using an electrochemical reaction and is very resistant to damp conditions. Perma Futura has an EX rating.

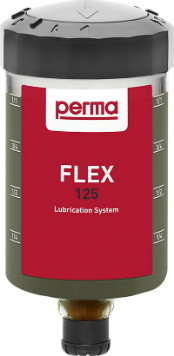

Flex

Perma Flex is a plastic-framed automatic grease that can be activated with a 60 cm³ or 125 cm³ control unit on the cover. The discharge time of 1 … 12 months can be chosen as suitable.

Perma Flex works best in an environment where the temperature is -20 … + 60 ° C. Perma Flex produces a maximum pressure of 5 bar using an electrically controlled electrochemical reaction and withstands very tight in all conditions. Perma Futura has an EX rating as well as an IP68 rating.

Nova

Perma Nova is a plastic-framed automatic grease that can be activated with a 65 cm³ or 125 cm³ reusable control unit. The discharge time of 1 … 12 months can be chosen as suitable.

Perma Nova works best in an environment where the temperature is -20 … + 60 ° C and is really accurate due to its own heat sensor and temperature measurement to give just the right amount of lubricant at all times. Perma Nova produces a maximum pressure of 6 bar using an electrically controlled electrochemical reaction and withstands very tight in all conditions. Perma Nova has an EX rating as well as an IP65 rating.

Star Vario

The Perma Star Vario is a plastic-framed automatic grease with a reusable control unit with a 60 cm³, 120 cm³ or 250 cm³ lubricant cartridge. The discharge time of 1 … 12 months can be chosen as suitable.

Perma Star Vario works best in an environment where the temperature is -10 … + 60 ° C and despite the changes in temperature and back pressure, it is really accurate to give just the right amount of lubricant all the time. The Perma Star Vario produces a maximum pressure of 6 bar while running an electrically controlled motor and it withstands very tight in all conditions. Perma Star Vario is IP65 rated.

Star Control

Perma Star Control is a plastic-framed automatic grease with a reusable control unit with a 60 cm³, 120 cm³ or 250 cm³ lubricant cartridge. The discharge time of 1 … 12 months can be chosen as suitable and the discharges can be timed based on the impulse only when the machines are running.

Perma Star Control works best in an environment where the temperature is -10 … + 60 ° C and is really accurate to deliver just the right amount of lubricant at all times, despite changes in temperature and back pressure. The Perma Star Control produces a maximum pressure of 5 bar while running an electrically controlled motor and it withstands very tight in all conditions. Perma Star Control has an EX rating as well as an IP68 rating.

Multi-point lubrication systems

If necessary, a multi-point lubricator can also be used in the machine or device. In this case, the lubrication device itself can be located between the objects to be lubricated and up to six lubrication points can be operated with one device.

Kraftmek delivers its imported Perma lubricator, lubricants and accessories directly from its own warehouse.

PRO MP-6 / PRO C MP-6

The Perma PRO MP-6 / PRO C MP-6 is a metal-framed, multi-point lubrication system with a programmable unit with a 250 cm³ or 500 cm³ replaceable lubricant tank. The discharge time can be selected from 1 day to 24 months. If a pulse-discharge option is selected, the discharge after each pulse is 1.00 cm³ per lubrication point.

Perma PRO MP-6 / PRO C The MP-6 works best in an environment with a temperature of -20 … + 60 ° C. The Perma PRO MP-6 / PRO C MP-6 produces a maximum pressure of 25 bar at six lubrication points up to five meters and withstands well even in harsh conditions. The Perma PRO MP-6 is powered by a replaceable battery and the PRO C MP-6 by an external 15-30V 120mA power supply. Perma PRO MP-6 / PRO C MP-6 can only be used with greases up to NLGI2.

PRO LINE / PRO C LINE

The Perma PRO LINE / PRO C LINE is a metal-framed, multi-point lubrication system with a programmable unit with a 250 cm³ or 500 cm³ interchangeable lubricant tank, specially designed for linear units. The discharge time and amount can be selected for each lubrication point separately and with different timing, depending on the need for lubrication at the site.

Perma PRO LINE / PRO C LINE works best in an environment where the temperature is -20 … + 60 ° C. The Perma PRO LINE / PRO C LINE produces a maximum pressure of 25 bar at six lubrication points up to five meters and withstands well even in harsh conditions. The Perma PRO LINE uses a replaceable battery and the PRO C LINE an external 15-30V 120mA power supply. Perma PRO LINE / PRO C LINE can only be used for greases up to NLGI2.

ECOSY

Perma ECOSY is a multi-point lubrication system with a plastic frame and a programmable unit with a 7000 cm³ refillable oil tank. The discharge time and amount can be selected for each lubrication point separately and with different timing, depending on the need for lubrication at the site. According to the pulse, the lubricating unit discharges 0.50 cm³ per lubrication point after each pulse. Each lubrication point can have its own settings for lubrication.

Perma ECOSY works best in an environment where the temperature is -20 … + 60 ° C. Perma ECOSY produces a maximum pressure of 10 bar at six lubrication points up to 10 meters. ECOSY uses an external 85-240V AC, 50-60 Hz or 24V DC, 25W power supply. Only oils can be used in Perma ECOSY.

Lubricator in the Perma collection

Perma automatic lubricators offer many advantages over traditional solutions. Manual lubrication is a thing of the past – automatic lubricators make your job easier, safer and save costs and the environment.

By using Perma lubricators, maintenance and downtime can be significantly reduced. Maintenance outages are also easily predictable and planned. Costs are reduced and the lubricator pays for itself quickly. The service life of important machine parts is extended – for example, up to 55% of roller bearing damage can be prevented by using Perma lubricators.

Occupational safety can be significantly increased with the help of lubrication devices. When using the Perma lubricator, it is not necessary to reach difficult lubrication points while the machine is running. The replacement interval of the lubrication cartridges is long and the replacement is fast. Nature also thanks, because the automatic lubricator optimizes the amount of lubricant used. No extra material is consumed and the machine stays clean. The lubricator can be used for both grease and oil lubrication.

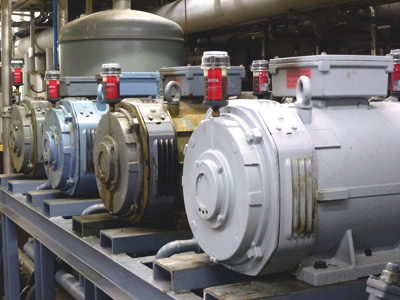

Typical applications for automatic lubrication equipment include e.g. Belt conveyors, electric motor drives, pumps and fans.

Belt conveyors are commonly used and often challenging equipment in many different industries. Reliable operation of the belt conveyor is often critical to the operation of the plant or process. Reliable lubrication is therefore paramount. The challenge for manual lubrication is the location of the conveyors in a high or awkward position. Lubrication must take place while the conveyor is running in order to work well. For occupational safety and reliability, the Perma lubricator is the absolute choice for these applications.

To ensure reliable operation and long life of electric motors, efficient lubrication is very important. Like conveyors, electric motors are often located in awkward places and are not lubricated. Over-lubrication also causes engine damage. With the help of Perma lubricators, these problems are easily solved.

Pumps and blowers often play a crucial role in almost all industries. At worst, a pump failure could stop the entire plant. Decomposition of a fan or blower can be a significant occupational safety risk due to dust, smoke, or gas. Properly dosed fresh and clean grease protects against dirt and water. Minimize risks by using Perma lubrication equipment.

Company presentation video

Principle of function

Applications

Ask our experts for more information

Markus Virkkala

markus.virkkala(at)kraftmek.com

+358 50 5930 074

Contact us using the form

KRAFTMEK 24/7