Gears and gearboxes

Renold Gears is a traditional gear manufacturer whose continuous development has resulted in one of the most comprehensive mechanical gears and gearbox selection.

For medium and heavy use

Renold Gears solutions are mainly targeted at medium and heavy use and are a great choice for both new and replacement applications.

Standard gears for the R, K, S and F series are also available with fast delivery.

R

The R-Series Gearboxes are compact in size and have good efficiency. Silence and reliability make these gears the ideal solution for many applications.

- In-line helical gear unit

- size classes 01.02.03.04.05.06.07.07.08.09, 10.13.14 and (16 not stock model)

- max. 20,000Nm, 160 kW

- gear ratios in two-phase i = 3.6 to 58, and i = 16200 in the combined version

- easy to adapt to IEC / NEMA standard motors

- cast iron frame epoxy-polyester powder coated

- sealed: the motor can be replaced without oil splashes

K

The K-Series bevel gearbox is a good choice when high torque is required combined with the smallest possible external dimensions. The K-series offers numerous options for mounting and the installation can be done horizontally or vertically.

- bevel helical gear unit

- sizes 03, 04, 05, 06, 07, 08, 09, 10, 12 and (15, 16, 18 are not stock models)

- max. 33,000Nm, 160kW

- gear ratios in three phases i = 8 to i = 160, and i = 35,000 in combination

- easy to adapt to IEC / NEMA standard motors

- cast iron frame epoxy-polyester powder coated

- sealed: the motor can be replaced without oil splashes

S

The S-Series worm gears are efficient bevel gears up to 10,000 Nm of secondary torque.

- Helical worm gear unit

- sizes 03, 04, 05, 06, 07, 08, 09 and 10

- max. 10,000Nm, 45 kW

- gear ratios i = 8 to i = 250 in two stages, and i = 60,000 in combination

- easy to adapt to IEC / NEMA standard motors

- cast iron frame epoxy-polyester powder coated

- sealed: the motor can be replaced without oil splashes

F

The F-Series cylindrical pin gearbox is a suitable choice for tight spaces. The gear unit type has proven its ability in demanding installation conditions. The collection includes a selection of foot, flange and sleeve shaft versions.

- Shaft mounted gear unit

- sizes 02, 03, 04, 05, 06, 07, 08, 09, 10, 11 and 12

- max. 16,500 Nm, 110 kW

- i = 5 – i = 100 in two phases and max. i = 5600 in the combined version

- cast iron frame epoxy-polyester powder coated

- sealed: the motor can be replaced without oil splashes

SMX

The pinion gears of the SMX series are solidly and with high quality, with hardened and polished gears as well as sturdy roller bearings. A wide range of gear ratios and options make the SMX series a good alternative to third-party gears with similar external dimensions. Ask for fast delivery time!

- secondary speed 10-400 rpm

- reversal prevention as option

- in addition to standard seals, special seals are available for difficult conditions

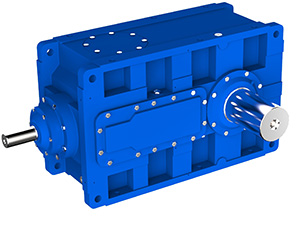

H

The H-Series heavy-duty gears are without compromise. 8 different sizes up to 162kNm.

- several different configurations

- wide range of ratios

- customized designs

- ATEX

TW

The TW is a heavy-duty worm gear for harsh conditions and heavy loads. In single or two-phase up to 1500 kW.

- several different configurations

- built from the best materials

- the unique Holroyd toothing guarantees high efficiency and a long life cycle

- reversal prevention as option

Gearbox condition monitoring

Renold Smart Gearbox

The importance of transmission oil maintenance is becoming increasingly important as technology and technical requirements evolve. Manual measurements may often stretch during the test and before the next inspection the lubricating properties of the oil may have completely collapsed. In this case, the bearings and gears are already damaged.

The Renold SmartGearbox OCMS system makes it possible to monitor the quality of the oil and its deterioration in real time. The communication is handled either mobile, so that the information about the oil degradation comes through the Apps to the mobile device, the IP67-protected Renold OQD display head or to the existing TCP / IP, CAN or MODbus system.

The measurement is performed with a broadband OQSx sensor developed in collaboration with Renold, which measures and calculates not only the lubricating properties of the oil, but also the particles and temperature present in it. Especially when using a mobile device, the result is easy to check at any time and the system sends an alarm when the oil quality deteriorates or the temperature starts to rise substantially.

For less critical transmissions, Renold also offers an MOT portfolio for on-site measurements. This complements the SmartGearbox-OCMS system well and makes oil monitoring of all gearboxes easy. In addition, there is nothing to prevent the combination of the SmartGearbox system and the MOT portfolio to also cover the maintenance of gearbox or hydraulic oils for rolling stock.

Videos

Ask our experts for more information

Markus Virkkala

markus.virkkala(at)kraftmek.com

+358 50 5930 074

Contact us using the form

KRAFTMEK 24/7